It is unique at a trade fair: a real factory will be set up during TechniShow. Nine different parties from the production technology set up a real integrated production automation. Visitors can experience all the steps of a modern production environment at this so-called Production Automation Theme Square. At the end of the "factory tour," a live product is actually waiting.

Eric Bakker, director/owner at Supplydrive, stands in the hallway in the BIC1 building at the Brainport Industries Campus in Eindhoven. Supplydrive deals with data exchange in the chain (external) and within a company (internal). Their software solution makes the different types of data generic, to make communication run smoothly. But right now, Bakker is busy. He waves his left arm in the air for a moment. Then he turns the palm of his right hand and presses his left finger into the vacuum next to his right hand.

Bakker has a hololens on his head and is visualizing the data between different systems. "We're integrating all the data streams from machines with each other," he says. "With this hololens, we can really show visitors what is happening. After all, it's hard to visualize software. Our challenge is that we now exist for eight years as a company and are in a beautiful location in Eindhoven, but users don't actually see us. With this hololens you can experience what is happening."

Basic Steps

Elise de Koning smiles as she sees Bakker waving his hololens on. De Koning is event manager at Cellro and put forward as spokesperson for the Production Automation Theme Square. "We have gathered a nice group of people to showcase the theme of production automation at TechniShow. We do that with a factory, where you can enter your own product and follow all the steps in it. The process can be seen both fully and partially automated."

The basic steps are robotization, automation, digitization and logistics integration. "The partners participating are all completing a step. To my knowledge, it is unique. Not only that there is a real factory at a fair, but also that competitors are working together. And we all think that in a modern manufacturing environment you have to cooperate precisely. A square like this doesn't come about if you don't see the bigger story. You have to transcend your own interests; it's the same in business."

How important is production automation? De Koning: "Extremely important. Everyone is working on it. And everyone is doing it in their own way; some parties are a bit further along than others. But it goes step by step. That journey is important. You also see that manufacturing companies are continuously orienting themselves to the next step in their process. With our Theme Square, we have brought all the steps together, in one place."

Link

Interestingly, there are two machine tools in the plant. On one side of the Theme Square, DMG has a DMU machine tool. On the other side of the corridor is Bendertechniek with a Brother machining center. Ed Dekkers, commercial manager at Bendertechniek: "On the production square, we are going to link a turning milling machine with a robot. This Brother is capable of processing both steel and aluminum. Just like in a real production environment, we have to be so flexible, because we don't know yet what material we will make the product from at the Theme Square. We are happy to participate in this unique and original project, and in this way we can profile Bendertechniek at Technishow."

Practice

Since data is crucial these days - especially when it comes to production automation - there are many parties involved in measurement. For example, Laagland contributes with Zoller presetting equipment. Michel Francken, product manager at Laagland: "By pre-setting, measuring tools for the machine tools and monitoring tool life, a production process is much more efficient. This allows us to turn on time that tools are there when they need to be there. At the Theme Square you can very nicely see a total concept with multiple suppliers from all branches of the sport. Exactly how it works in practice."

Heidenhain is supplying state monitoring software to the factory at Theme Square. "With that, you can check the status of the machinery, so you get insight into the efficiency of the machines," says Paul Venema, account manager at Heidenhain. "At the plaza, we collect the data and link it to the ERP system. We all want to show that you can go through the process without adding data manually. Simply put: the data goes into the process, the hands off and at the end a ready-made product comes out. We want to show that all the machines and systems talk to each other. And understand each other."

Series size

Renishaw also plays a role in the measurement steps at the Theme Square factory. Philippe Reinders Folmer, general manager at Renishaw Benelux, says: "Before a part goes into the machine, we measure whether it can be machined properly. In the machine we check tools; whether they are long enough, have the right diameter and may be broken. And we check the workpiece, both in and beside the machine. Remember, a machine is blind, so to speak. Measuring allows you to correct during machining so that the whole thing stays within tolerances. Especially in an automated process, it is crucial that the products coming out of the machines match what you want to produce."

Production automation is playing an increasing role in the manufacturing industry in the Benelux, according to Reinders Folmer. "We want to get the cost price down, and also keep flexibility in the products. Actually, you want to get to an automated batch size of 1. In the Benelux, the manufacturing industry is already doing well, especially compared to other countries. However, there is even more to see at TechniShow. The funny thing is that on the Theme Square you see a number of companies that were competing with each other and are now working together. So as a visitor, you can make choices. You're not tied to one party. There are many solutions."

"Tool and product management systems (veding systems) are a crucial component in a factory like this," continued Henry Blom, general manager of Hoffmann Group Netherlands and Belgium. "Especially since our TOOL24 systems can be seamlessly linked to ERP software, they are indispensable for closing the digital process chain. We therefore think the theme square is a fantastic initiative, because it gives visitors to the TechniShow a very enlightening look at what possibilities there are in the field of production and process optimization and what benefits this brings."

Mission

Back to the hallway, where Erik Bakker of Supplydrive is still busy with his hololens. Henk Abbring, director and owner of MKG Nederland, is now also there. Abbring, with his MKG Nederland, has been developing and implementing ERP software for SME metal companies in the manufacturing industry since 2000. MKG Netherlands is headquartered in Hengelo, but last year the company opened a branch at the Brainport Industries Campus (BIC) in Eindhoven.

Meeting at the MKG office

"With our MKG ERP software, we ensure that data can be shared throughout the plant. This allows us to easily see if everything has gone as it should, without the need for human intervention. We thus provide a digital factory and are the administrative beating heart of a company. Our mission is to enable companies to perform excellently. This is only possible if you work together and connect well. At the Theme Square we can present and shape this. This square is right up our alley, because this is what we do every day. MKG is also a Smart Industry Ambassador in the Smart Industry Fieldlab 'Smart Connected Supplier Network' (SCSN) that aims to strengthen the Dutch manufacturing industry and realize the digital factory. We all show a clear story at Technishow that is relevant to the entire manufacturing industry."

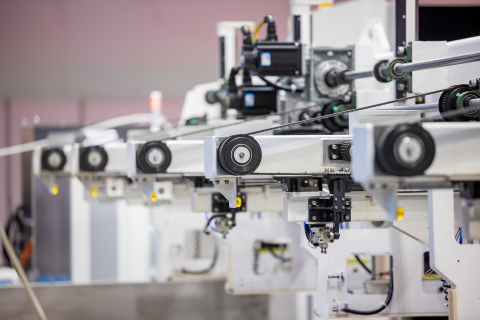

The factory

The factory at the Theme Square is a live setup similar to that found in a real manufacturing plant. That includes order intake, tools, an AGV, integration with machines, robotic cells and all the associated software. At the time of writing, nine parties are participating: Bender Technology, Cellro, DMG Mori, Heidenhain, Hoffmann Group, Lowland, MKG, Renishaw and SupplyDrive. The Theme Square was made possible in part by the industry associations FPT-VIMAG and NEVAT. If you have questions about the Production Automation Theme Square, please contact Ires Veerman, branch manager FPT-VIMAG, at ires.veerman@fme.nl.