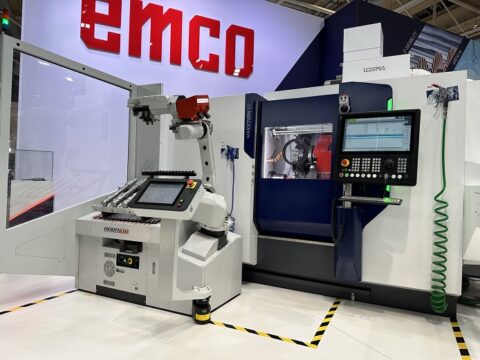

Van Dulst Techniek BV is a wholesaler for tools and machines for installation and construction companies as well as industry. Van Dulst provides professional, service-oriented and reliable advice in the field of tools and machinery for metalworking, construction and installation companies. At TechniShow, Van Dulst shows several talking installations, such as the machining center Mecal MC305 Kosmos TM with a spherical robot loader attached.

The Mecal 305 Kosmos TM is a compact 4-axis CNC controlled machining center specifically for aluminum or steel profiles. The working length is 4,225mm, Y axis 530mm, Z axis 410mm and an A axis of 125 degrees, also equipped with a tool magazine with 8 positions."

Arjen van Dulst, owner Van Dulst Techniek BV, explains: "This means that the automatic loading and unloading of the profiles, which is a labor-intensive job, can be solved with an automatic loader, in this case a Yaskawa Robot. The whole thing can be delivered integrated."

"In addition, the 24L CNC circular saw machine will be shown with a long stroke feed magazine and expandable with an MPS loading and unloading system. The circular saw machine has a 610mm saw blade and long radial stroke with a clamp retraction system. This allows large aluminum profiles to be shortened without damage. This machine is in high demand and application in a short time."

Van Dulst also shows what MPS can do in terms of production automation and production lines. From simple stop systems to complex loading warehouses linked to operations such as cutting, drilling, milling and punching. Arjen explains: "MPS is constructed, assembled and installed in Krimpen aan den IJssel before it is installed. In short: home-grown machine building. When it comes to machining complex profiles, Van Dulst Techniek with MPS is a suitable supply partner to work with."

"MPS recently started offering the in-house developed control system MPS control. The great advantage of MPS control is its linkability to any ERP system. The production preparation and operations can be sent to the machine control after which the operations can be realized after activation, but otherwise entirely without intervention of an operator input. A 3D simulation is included. MPS control is suitable for the aforementioned operations and can be built up modularly. We will also demonstrate this at TechniShow.

At TechniShow, Van Dulst will also show the new Soco fully automatic profile laser. This is a European first, as this machine will only be on display in Germany a month later. Arjen explains: "The Soco SLT-80 is a fiber laser installation with 10 controlled servo motor shafts and a capacity of 12 to 80mm. The machine comes standard with a 1.5 kW fiber laser source (2 kW and 3kW possible) and is extremely fast. Soco introduces a new concept where the laser is mounted on the moving output clamp. This gives several advantages in speed and extremely short residual pieces. Furthermore, there is the well-known Soco i2 CNC control on the machine as well as the IRMS (Internet Remote Monitoring System). In addition, this machine is particularly well priced."

You can find Van Dulst Techniek BV in hall 8, booth 08.D070 |Meet now